- 0086-512-58361938

- michael@victory-chem.com

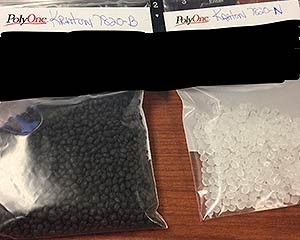

Kraton G polymer is the hardest, most diluting, and most compatible with polyolefins and mineral oils of all styrene thermoplastic block copolymers. The Kraton G series is a block copolymer of the second generation of polystyrene and partially hydrogenated rubber. Partially hydrogenated rubber may be styrene-ethylene/butene-styrene (SEBS) or styrene-ethylene/propylene-styrene (SEPS). They are used for occasions requiring UV resistance, high temperature and processing stability. Kraton G polymer is a soft, powerful compound for producing handles and handles, elastic components in diapers, oil gels for telecommunications and medical applications, impact modifiers for engineering thermoplastics, and preferred material for toughening agents / toughening agents for transparent polypropylene.

Kraton D SIS polymer is the softest of the brand. It has low modulus and is the preferred polymer for pressure sensitive applications. It exhibits low viscosity and provides high strength and excellent elasticity. These thermoplastic resins are easy to process and are compatible with various tacky chemicals.

We mainly supply the following products made in the United States and Taiwan, packed in 25 kg bags or 600 LB bags from Koten’s original factory.

EAA (ethylene acrylic acid copolymer) film has good flexibility, impact resistance, and transp......

Time:2024-01-17

Ethylene Acrylic Acid Copolymer (EAA) Ethylene acrylic acid copolymer (EAA) is a material with......

Time:2018-09-29

Ethylene Methacrylic Acid (EMAA): Ethylene methacrylic acid copolymer (EMAA) is a resin obtain......

Time:2018-09-29

Polyisobutylene(PIB) production and application: a. The molecular weight is stable, the dist......

Time:2018-09-29